INDAG – die FlowMix Company

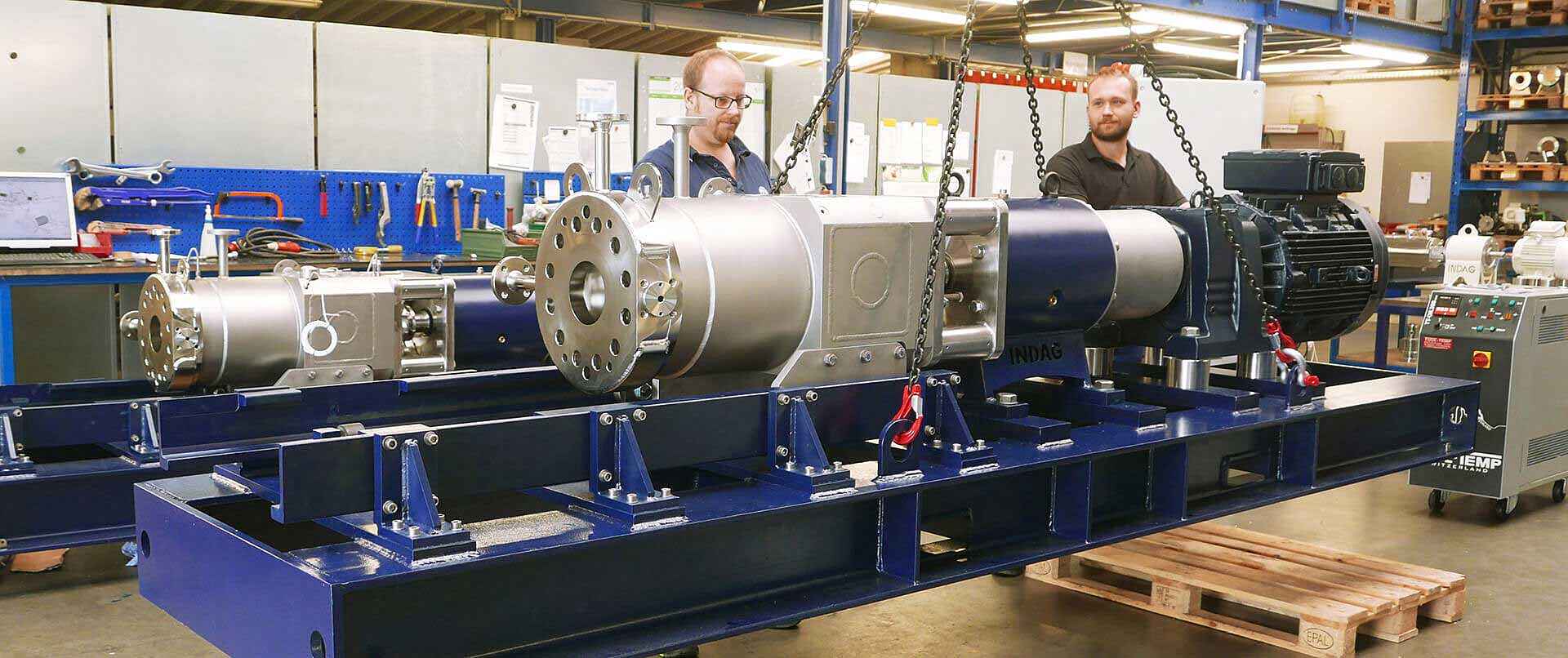

INDAG ist der Experte für dynamische kontinuierliche Inline Mischer.

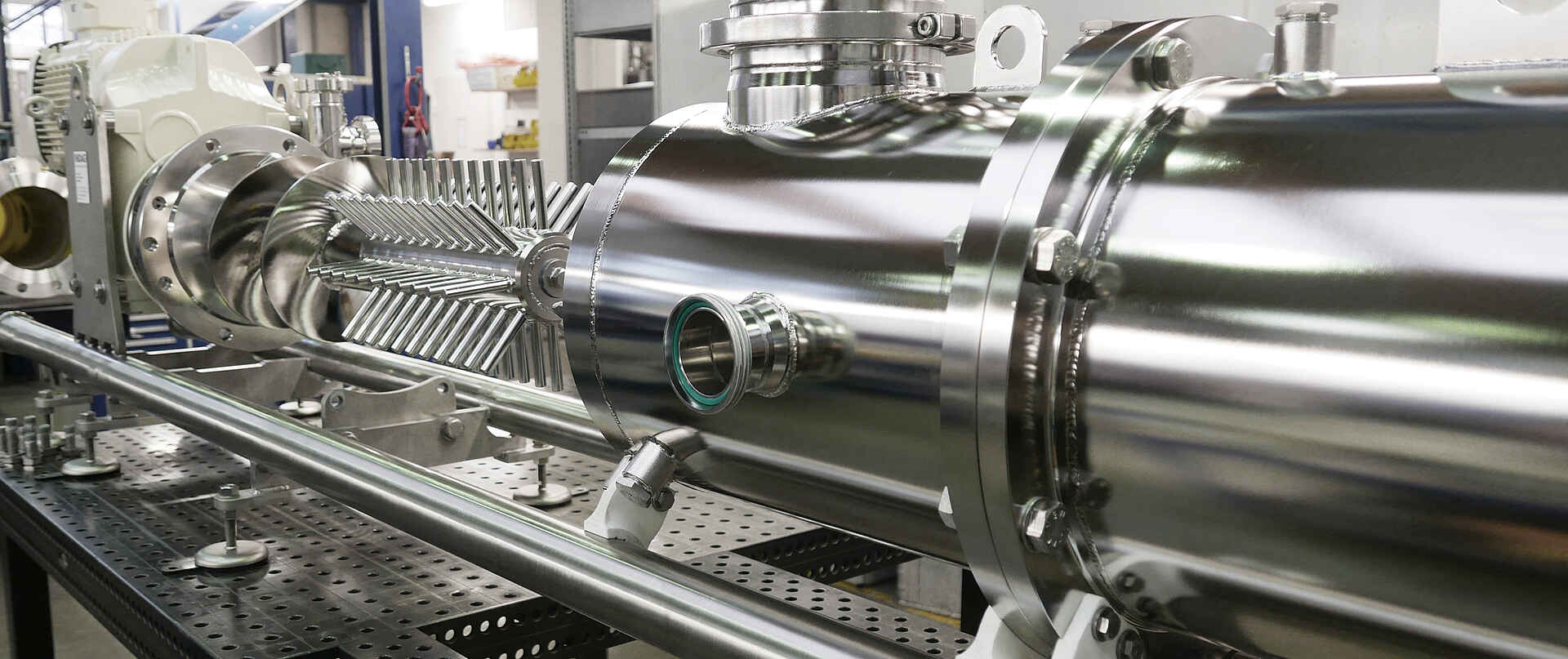

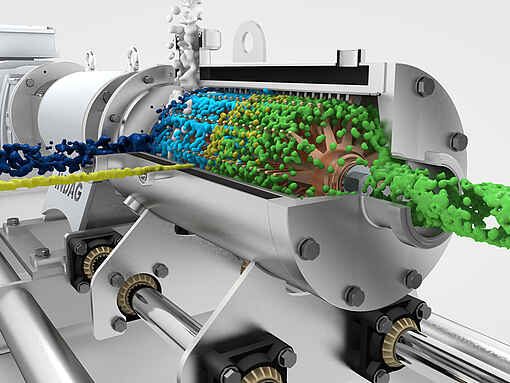

INDAG Mischer werden eingesetzt für homogene Mischungen, Emulsionen und Dispersionen sowie für das Belüften von Produkten mittels Gaseinmischung oder das Aufkochen durch Einmischen von Wasserdampf. Das Produktportfolio reicht vom schonenden Mischen über das intensive Mischen bis zum high shear Mischen. Dabei werden die dynamischen Inline Mischer in Produktionen, Laboren oder Pilotanlagen eingesetzt. INDAG Mischer bestehen aus standardisieren Komponenten, die Produkt- und Anwendungsspezifisch auf die Bedürfnisse der Kunden zugeschnitten werden.

News

Branchen

Unsere dynamischen Inline Mischer finden vielfach Anwendungen in den Bereichen Lebensmittel, Süßwaren, Milchindustrie, Getränke, Chemie, Klärtechnik, Kosmetik, Pflanzenöl und vielen weiteren. Die kontinuierlichen Durchlaufmischer werden zum Emulgieren, Dispergieren, Mischen, Auflösen, Aufkochen, Verdünnen, Belüften, Aufschäumen und auch zum Zerkleinern eingesetzt.

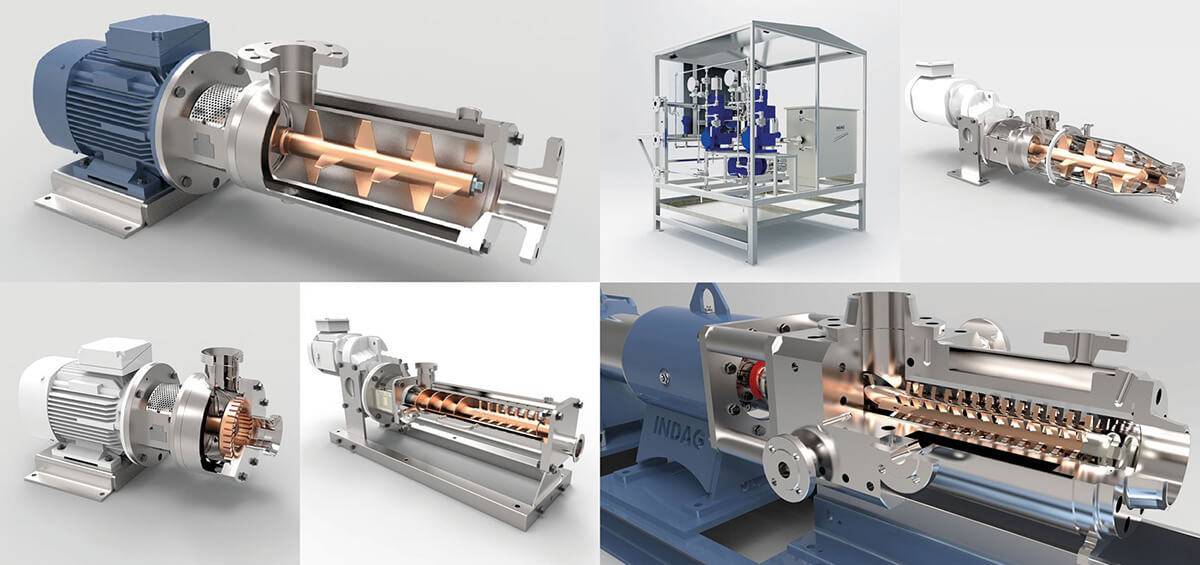

Produkte

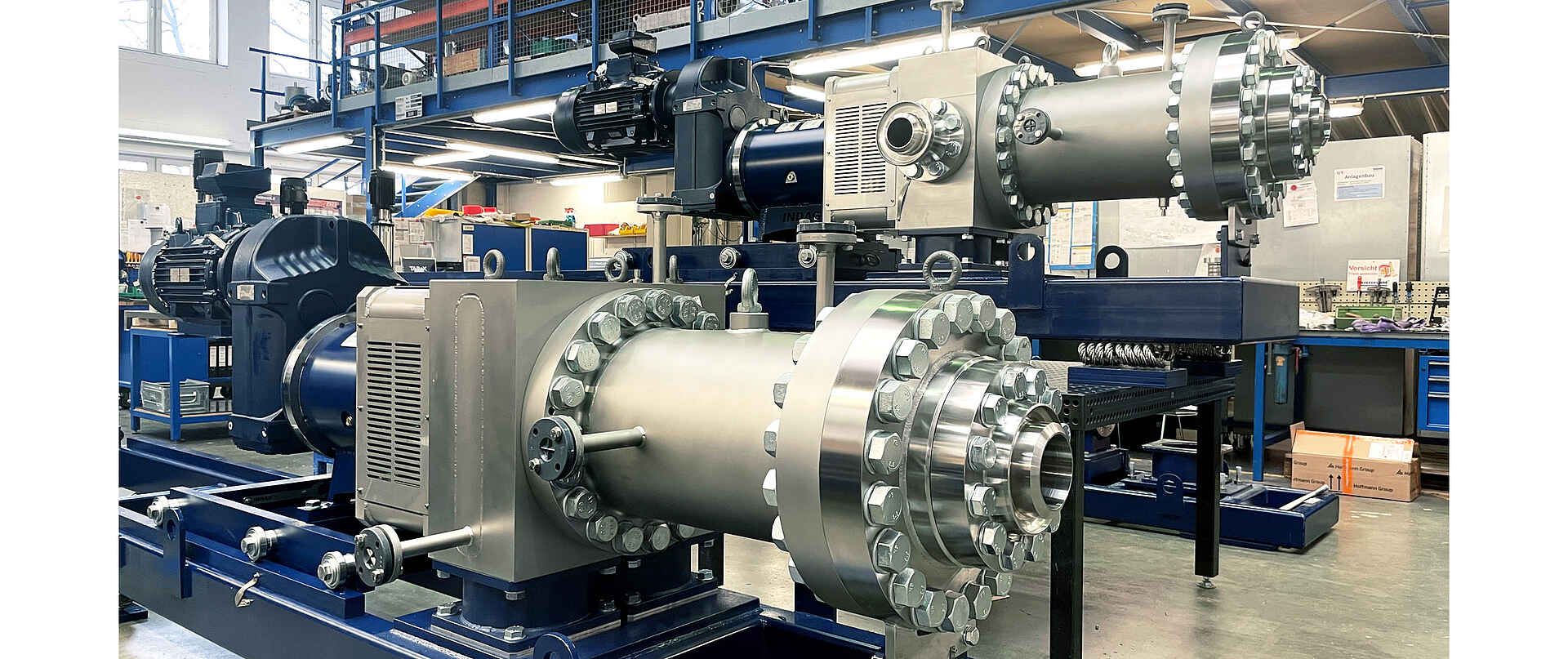

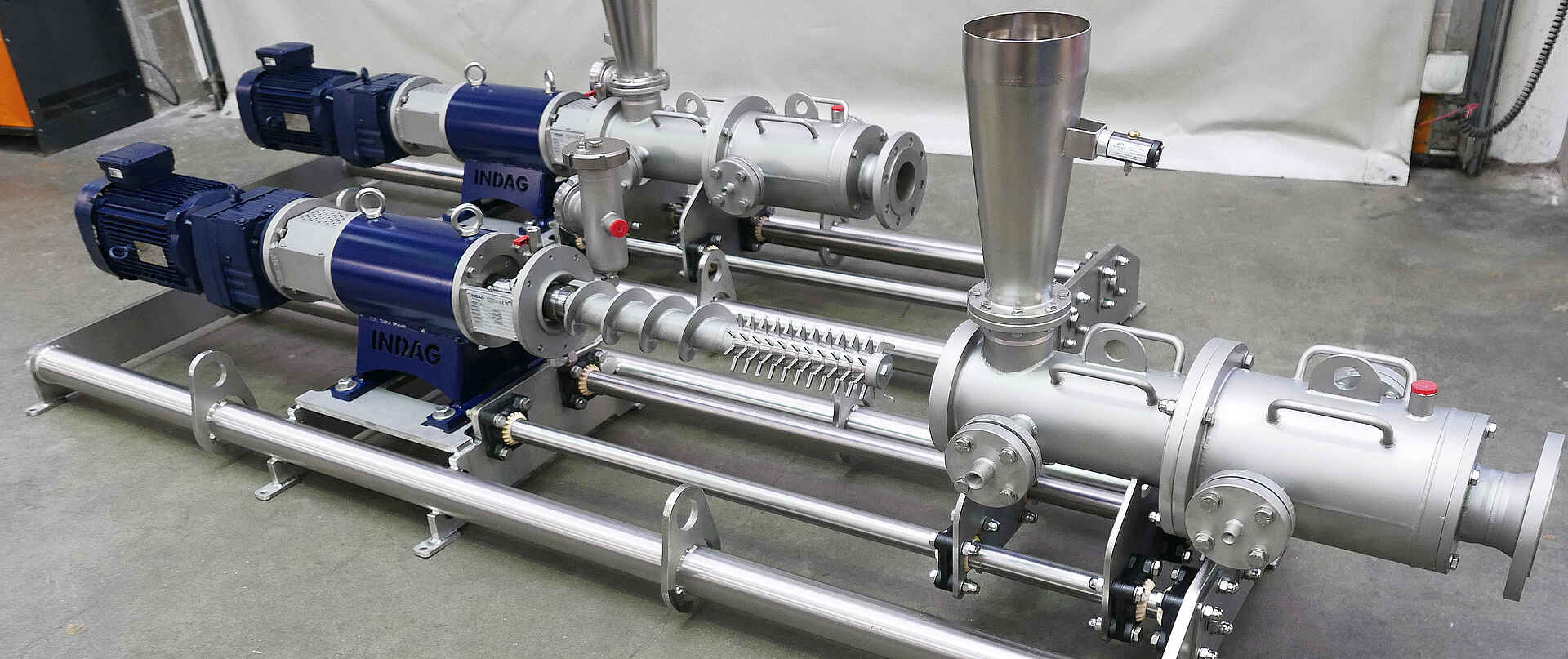

Wir haben für Ihre Anwendung die passenden Mischer: Hygiene-Mischer, Aseptik-Mischer, Industrie-Mischer Hochdruck-Mischer, Hochviskos-Mischer, Hochtemperatur-Mischer, Fest-Flüssig-Mischer, High shear Mischer, Dispergierer, Emulgierer, Labor-Mischer oder auch Technikums-Mischer.

Das Portfolio unserer dynamischen Inline Mischer bildet unterschiedlichste Scherraten vom schonenden Mischen über das Intensive Mischen bis hin zum Emulgieren oder Dispergieren ab.

Die neueste Entwicklung, unser INDAG Fest-Flüssig-Mischer, wird eingesetzt um kontinuierlich und schonend Pulver mit Flüssigkeiten oder Granulate mit Flüssigkeiten zu mischen.